Call: 08045478892

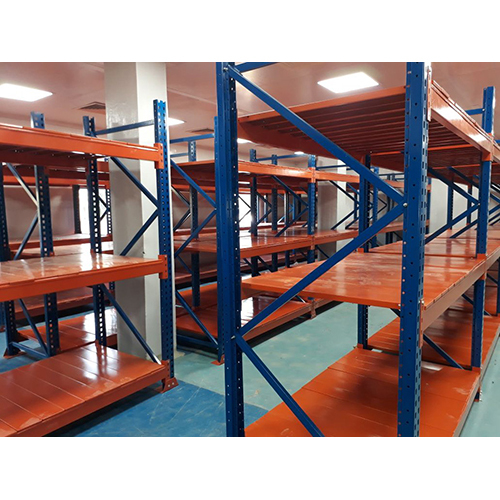

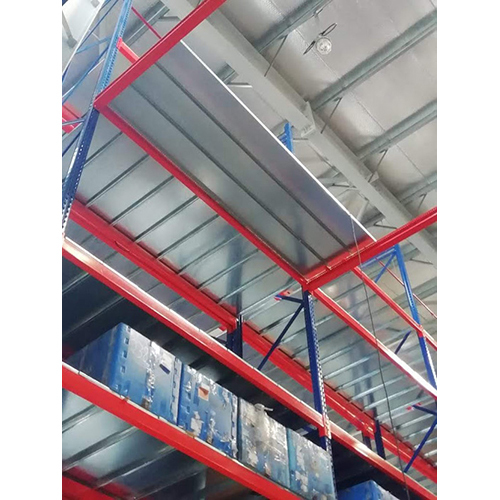

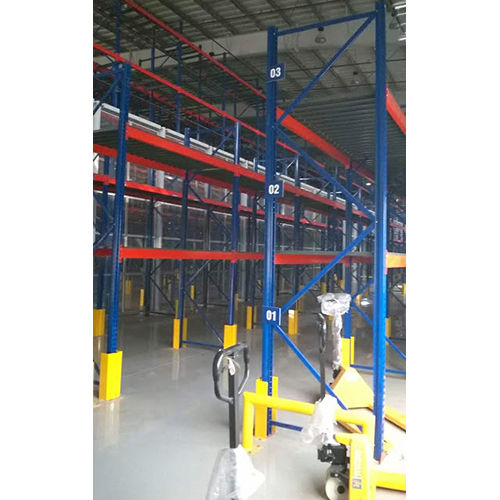

Industrial Heavy Duty Rack

8000 INR/Unit

Product Details:

- Color Blue and Red

- Usage Industrial

- Size Different Size

- Product Type Industrial Heavy Duty Rack

- Material Steel

- Shape Rectangle

- Application Industrial

- Click to View more

X

Industrial Heavy Duty Rack Price And Quantity

- 8000 INR/Unit

- 10 Unit

- 5000.00 - 32000.00 INR/Unit

Industrial Heavy Duty Rack Product Specifications

- Industrial

- Blue and Red

- Industrial

- Industrial Heavy Duty Rack

- Rectangle

- Different Size

- Steel

Industrial Heavy Duty Rack Trade Information

- Cash Advance (CA)

- 5000 Unit Per Month

- 20-25 Days

- All India

Product Description

Industrial heavyduty racks are specialized storage solutions designed to withstand the demands of industrial environments where large and heavy items need to be organized and stored efficiently These racks are commonly used in manufacturing facilities warehouses distribution centers and other industrial settings Here are some key features and considerations associated with industrial heavyduty racks

Material Construction

Steel Construction Industrial heavyduty racks are typically made from highquality steel or other robust materials Steel provides the necessary strength and durability to handle heavy loads and withstand the rigors of industrial use

Load Capacity

High LoadBearing Capacity These racks are engineered to support substantial weight capacities They are designed to accommodate heavy items such as machinery parts tools raw materials or finished products

Structural Integrity

Reinforced Design The structural design of industrial heavyduty racks often includes reinforced beams columns and crossbracing to enhance stability and prevent deformation or sagging under heavy loads

Configuration Options

Pallet Racking Systems Many industrial heavyduty racks take the form of pallet racking systems These systems allow for the efficient storage of palletized goods facilitating easy loading and unloading with forklifts or pallet jacks

Adjustability Some industrial racks offer adjustable shelving or modular components providing flexibility to accommodate varying sizes and types of items

Safety Features

Safety Clips and Locking Mechanisms Industrial heavyduty racks often incorporate safety features such as locking mechanisms and safety clips to secure beams and prevent accidental dislodging of components

Load Rating Information Components of the rack are typically marked with load ratings ensuring that users adhere to weight limits and safety guidelines

Fire Safety

FireResistant Design Depending on the industry and regulations industrial heavyduty racks may be designed with fireresistant materials to enhance safety in the event of a fire

Application

Wide Range of Uses Industrial heavyduty racks are versatile and can be used to store a variety of items including raw materials heavy machinery components automotive parts and other industrial goods

Installation and Assembly

Professional Installation Given the complexity and loadbearing requirements the installation of industrial heavyduty racks is often done by professionals to ensure proper assembly and adherence to safety standards

Customization

Tailored Solutions Manufacturers may offer customization options allowing businesses to tailor the rack systems to their specific storage needs including dimensions load capacity and configuration

Selecting the right industrial heavyduty rack system depends on the specific requirements of your industrial operation including the types of items to be stored space constraints and safety considerations Its important to work with reputable suppliers and ensure that the chosen rack system meets industry standards and regulations

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese